The government’s reaction to the coronavirus of shutting down the normal economy has unsurprisingly inspired some business owners to contemplate shifting to non-human means of production by using machines that don’t get sick.

One blog stated the objective clearly in a recent headline: Coronavirus May Mean Automation Is Coming Sooner Than We Thought, SingularityHub.com, March 19, 2020:

. . .Peter Xing, a keynote speaker and writer on emerging technologies and associate director in technology and growth initiatives at KPMG, would agree. Xing believes the coronavirus epidemic is presenting us with ample opportunities for increased automation and remote delivery of goods and services. “The upside right now is the burgeoning platform of the digital transformation ecosystem,” he said. . . .

Indeed, some quarters see the epidemic as a swell opportunity to switch to automation and away from annoying human workers who demand paychecks and lunch breaks.

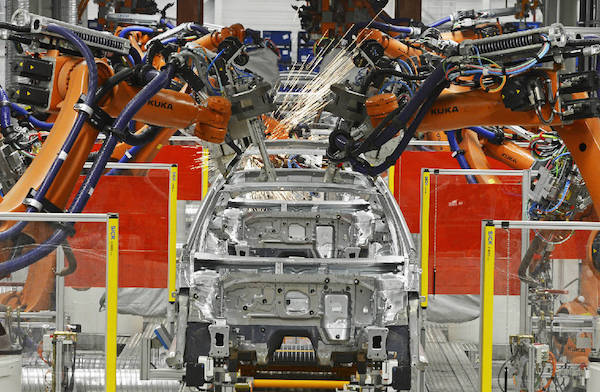

Some industries, like automotive manufacturing (shown below), already have machine-only areas of production.

In China, businesses see an immediate need for service robots as well as more automation in factories:

Robots rising: Coronavirus drives up demand for non-human labour in China, Reuters, March 20, 2020

SHANGHAI, March 20 (Reuters) – A shortage of workers and restrictions on human contact because of the coronavirus pandemic is driving up demand for service robots in China, potentially boosting a sector that has struggled to scale up commercially.

Venture capitalists with expertise in the robotics sector said they are anticipating orders from China to rise significantly this year, based on interest since the end of January when the virus began spreading in China.

That could take the use of service robots from novelties that deliver food and drink in restaurants and hotels to an army that performs essential functions in hospitals bound by strict no-contact rules.

“The healthcare segment has been really hot,” said Emil Jensen, vice president of China sales for Denmark-based Mobile Industrial Robots, which makes customisable robots that are used both in hospitals and on factory floors. [. . .]

FACTORY AUTOMATION

Along with the service robots, the coronavirus pandemic could spur demand for more automation at factories.

Many Chinese semiconductor plants located in the virus epicentre of Wuhan have run continuously throughout the outbreak, which chip industry experts attribute to their highly automated production processes.

Still, the virus itself also presents an obstacle to widespread long-term adoption of automation because of the economic stress it is imposing on many companies.

Huan Liu of Mujin, which makes intelligent robot sorting and picking systems, said companies often must spend millions of dollars for a basic automation project, which can take six to twelve months to complete.

“For new customers, it depends on which factor is stronger,” said Liu. “The need to replace labour during the virus, or the need to balance the budget as sales go down during the virus.”